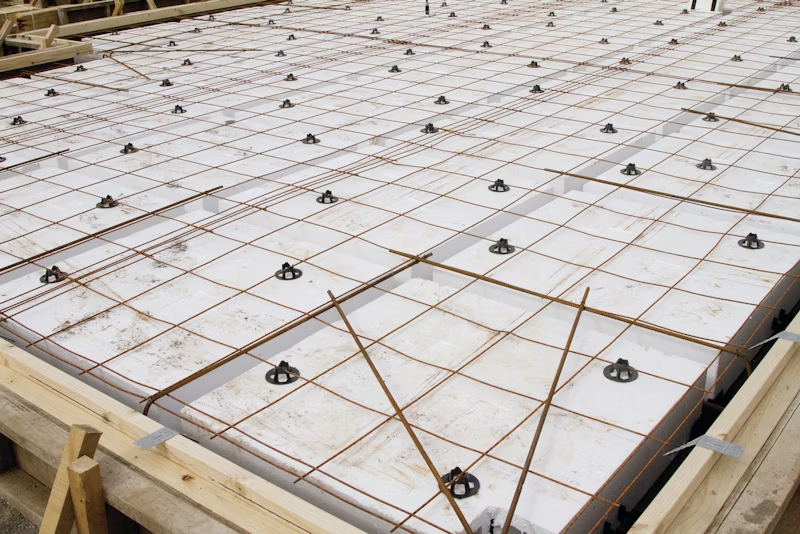

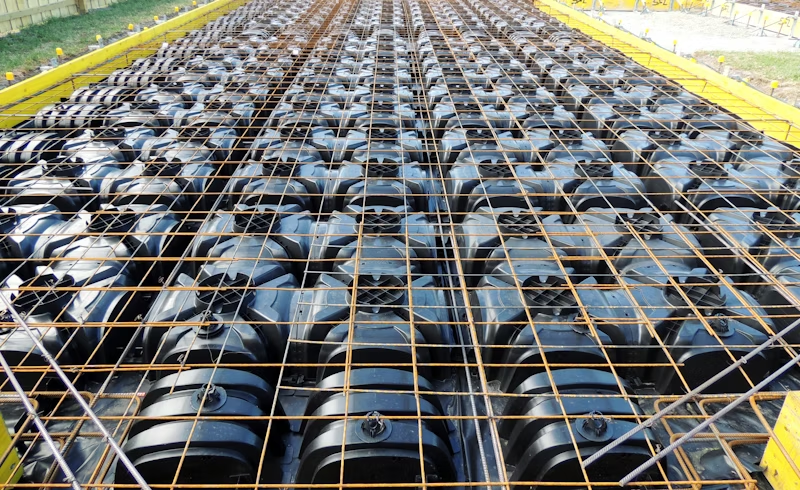

SuperSlab | Concrete Slab Foundations

Gallery

Frequently asked questions

Why choose SuperSlab?

SuperSlab is a fully engineered and compliant concrete foundation system. It offers time and cost savings, while enhancing energy efficiency and structural strength. SuperSlab is CodeMark certified and BRANZ appraised for peace of mind.

Where can I get the SuperSlab Technical Manual?

You can download the latest version located in our document library.

Does SuperSlab improve insulation?

Yes. SuperSlab offers improved R-value and thermal mass, creating a warmer floor. SuperSlab+ enhances this further with a fully insulated or edge-insulated system that exceeds standard thermal requirements.

Are shear keys required with SuperSlab?

Not usually. Shear keys aren’t required under CodeMark unless specific seismic conditions apply. In seismic zones (e.g., Christchurch), shear keys are still recommended unless soil conditions indicate lateral spreading; however, this will be determined by an engineering team in the design process.

Is SuperSlab BRANZ appraised?

Yes, BRANZ appraisal No.964 (2017) acknowledges that a SuperSlab flooring system complies with the New Zealand building code. If a SED is required, PS1 and PS4 statements will be required when lodging a consent.

What is a PS1? A Design Producer Statement. This is confirmation from an engineer that it is designed to the New Zealand Building Code.

What is a PS4? A Construction Review Producer Statement. This is confirmation from an engineer that it has been constructed in accordance with the details shown on the consented documents relating to the PS1.

Do councils accept SuperSlab?

Yes. When CodeMark conditions are met, councils must accept SuperSlab. All supporting calculations and drawings are provided by the slab designer and can be submitted with your initial building consent or as an amendment.

How long does it take to get plans engineered?

If your site qualifies as ‘good ground’, engineering isn’t required under CodeMark. If an SED is needed, design generally takes 3-5 working days.

Does SuperSlab use more concrete than a standard slab?

SuperSlab includes rib structures that average around 125mm of flat concrete. However, this is offset by savings in:

- Excavation and disposal

- Hard fill requirements

- Block perimeter foundations

Is SuperSlab faster to install than conventional slabs?

Yes. Experienced contractors can install a SuperSlab in approximately 3 days. Traditional footings typically take around 2 weeks, resulting in significant time and labour savings.

Can SuperSlab be used on sloped sections?

Yes. SuperSlab works well on sloping sites. Minor steps can often be poured in a single pour. For more significant level changes, the retaining wall footing is integrated into the lower slab, reducing excavation. Stepped floors may require SED.

What’s the maximum weight SuperSlab can support?

The standard SuperSlab system is designed for 2.5 kPa (suitable for residential garage loads). With specific design input, the system can be upgraded to handle loads up to 10 kPa. Reinforcement and topping thickness may vary for heavier applications.

Can SuperSlab be used on soft ground?

Yes. SuperSlab can be used on sites with an allowable bearing pressure starting at 50 kPa (as per Table 1 in the SuperSlab Technical Manual). For other ground conditions, a Specific Engineering Design (SED) may be required. The system can also span between piles on poor ground or deep topsoil, making it suitable for a wide range of land classifications.

Can any builder install SuperSlab?

Yes, any qualified builder can construct a SuperSlab foundation when following the supplied plans and construction specifications.